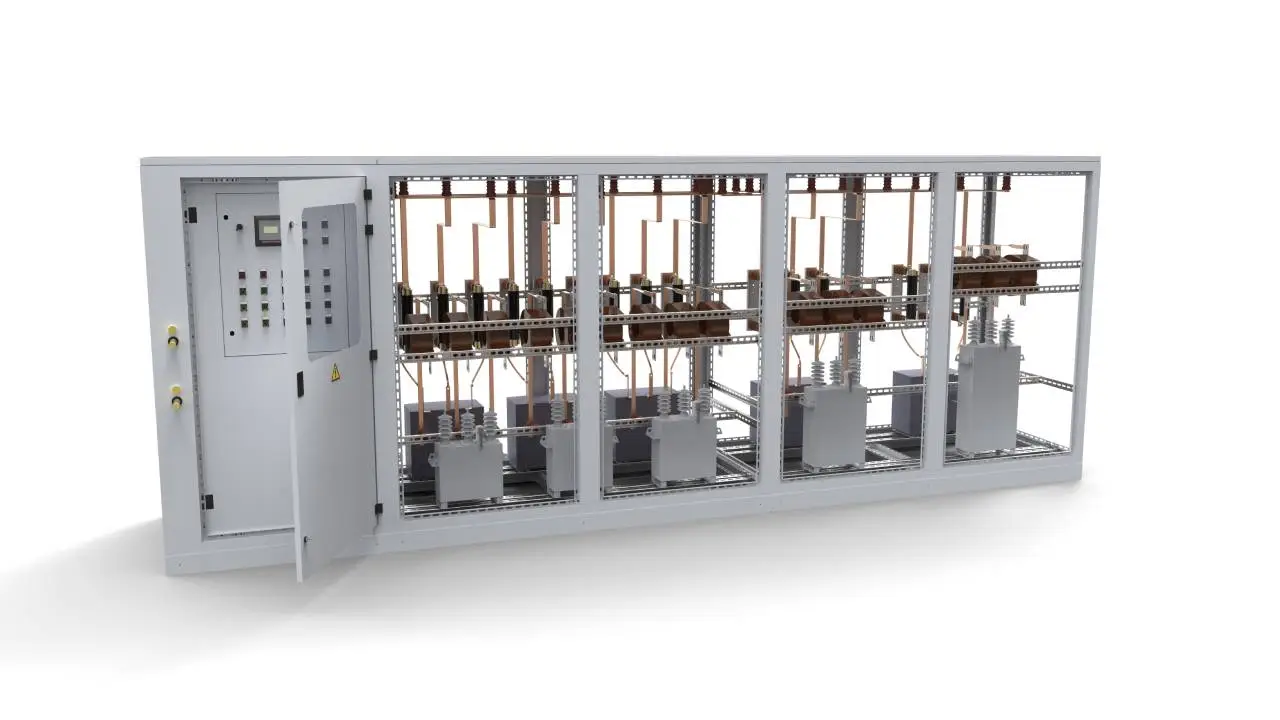

In planning an electrical system, one of the most important things to consider is choosing the right architecture to fit the system’s needs. Picking the right system architecture can ensure smooth operations and easy maneuverability when the system is up and running. Here are some aspects to consider when selecting the architecture for a system:

- System Continuity: Industries like chemical plants, fertilizer production, and other petrochemical industries often require high continuity to avoid disrupting production processes and minimizing downtime. Continuity ensures that the system runs smoothly without interruptions, which is crucial for industries relying on continuous production processes.

- Power Generation: The choice of architecture should also consider power generation. This means ensuring that the system can generate enough power to meet the demands of the operation. Proper power generation ensures that the system has sufficient energy to power all the equipment and machinery required for operation.

- Cost: Cost is another important factor to consider. Choosing the right architecture can help minimize initial investment costs and ongoing operational expenses. By selecting an architecture that is cost-effective, companies can allocate their resources more efficiently, ensuring that they get the best value for their money.

- Future Expansion: When selecting an architecture, it’s essential to consider potential future expansions, such as increased load demands or the addition of new electrical pathways or generating units. Planning for future expansion ensures that the chosen architecture can accommodate growth without the need for significant redesign or investment in the future.

Types of ELectrical Architecture

There are typically three types of electrical architecture. Electrical Architectures include the following:

- Radial system

- Loop System

- System with internal power generation

Radial System

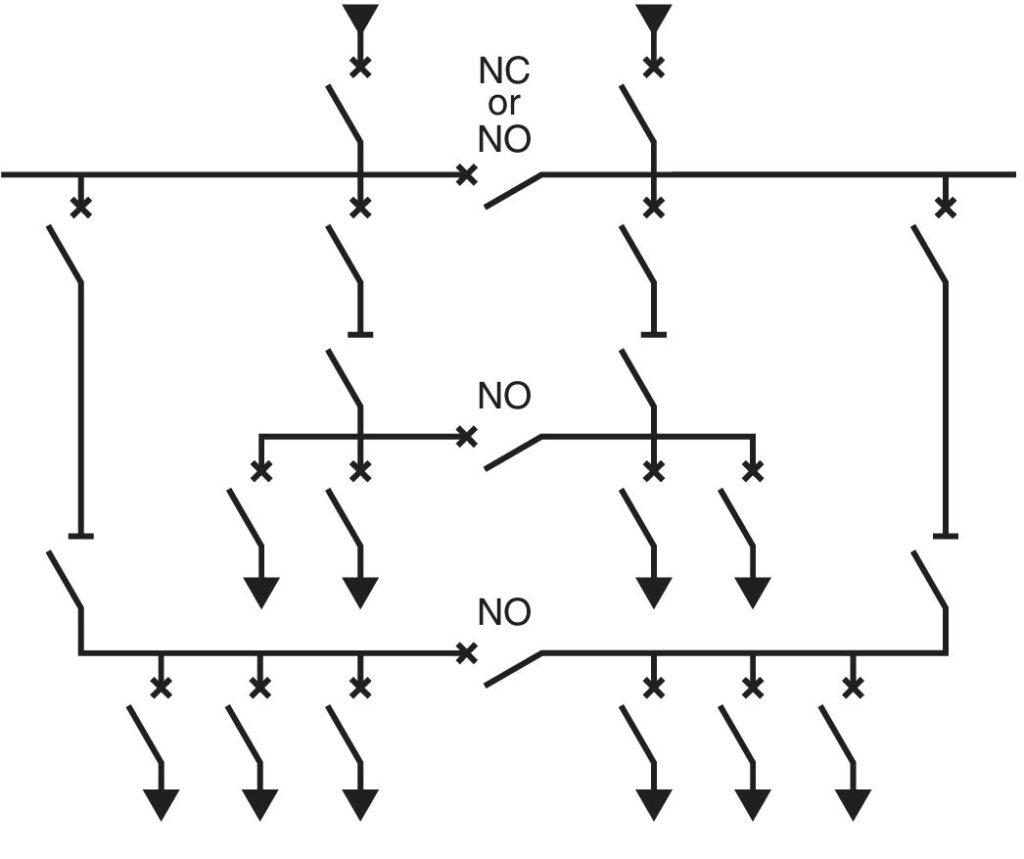

A radial system is where electricity flows in a single direction, from the source downward along a single path. This type of system is suitable for applications that don’t require high supply continuity because if there’s a disturbance in the feeder line, many of the loads may lose power. In terms of cost, a radial configuration is inexpensive to set up initially, but its flexibility is limited since it lacks alternate paths, rerouting power in case of a fault can be challenging, potentially leading to longer downtimes for repairs or maintenance. There are several types of radial system, including:

- Single Feeder: a radial single feeder configuration is suitable for system that doesnt require continous supply operation. The advantage using this configuration is on the minimum cost required since it is the most simple configuration and doesnt require complex protection. Some drawbacks of this configuration including low availabilty, longer downtime, and a single fault may intterupt the entire feeder

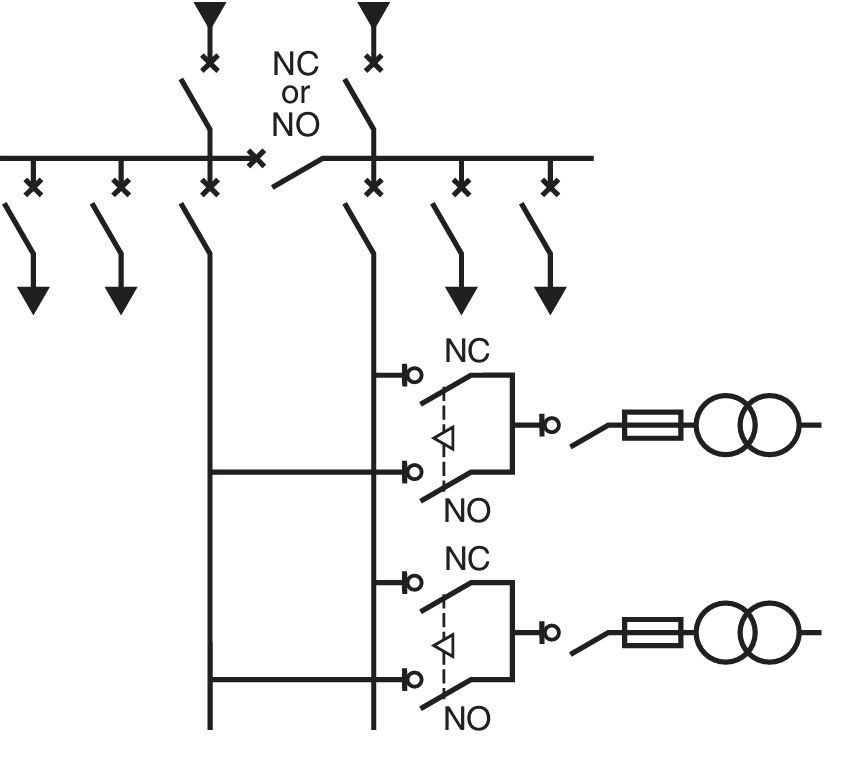

- Double Feeder: Unlike single feeder configuration, double feeder can offer continous operation due to its good manuverability. in case of one busbar in undermaintenance, the supply could still continuues for all the load. the Drawback of this confiiguration lies on its expensive cost.

- Parallel Feeder: A parallel feeder configuration is suitable for large power system but the flexibilty to future expansion is limited. This configuration also offers good continuity and simple protection

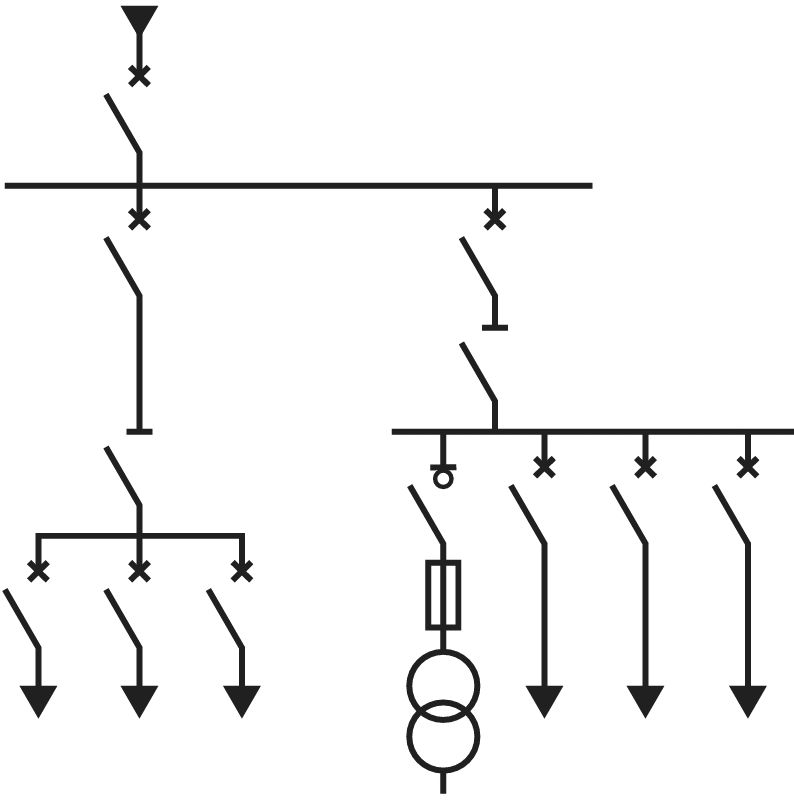

Loop System

A loop configuration refers to a network layout where multiple power lines or circuits form a closed loop, enabling redundancy and alternate paths for power flow. This design enhances reliability, as it reduces the risk of a single point of failure disrupting the entire system. Additionally, loop configurations can improve fault tolerance and facilitate maintenance without interrupting power supply to consumers. There are two types of loop system:

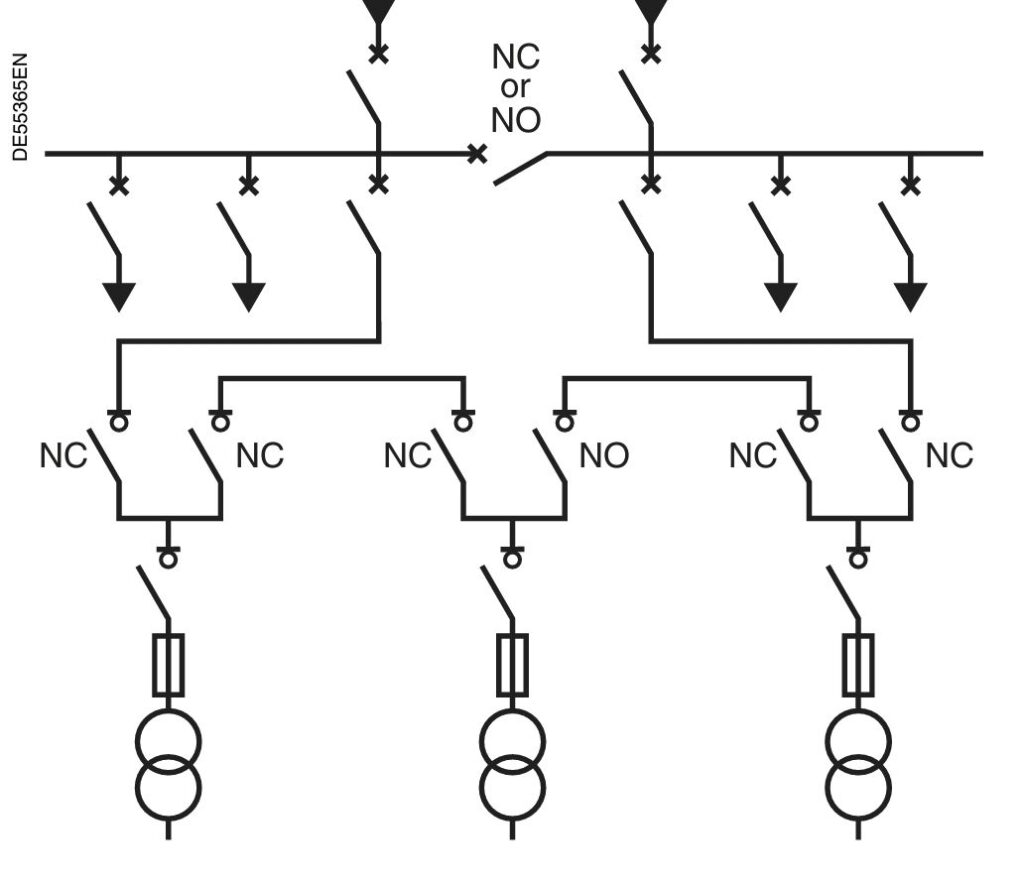

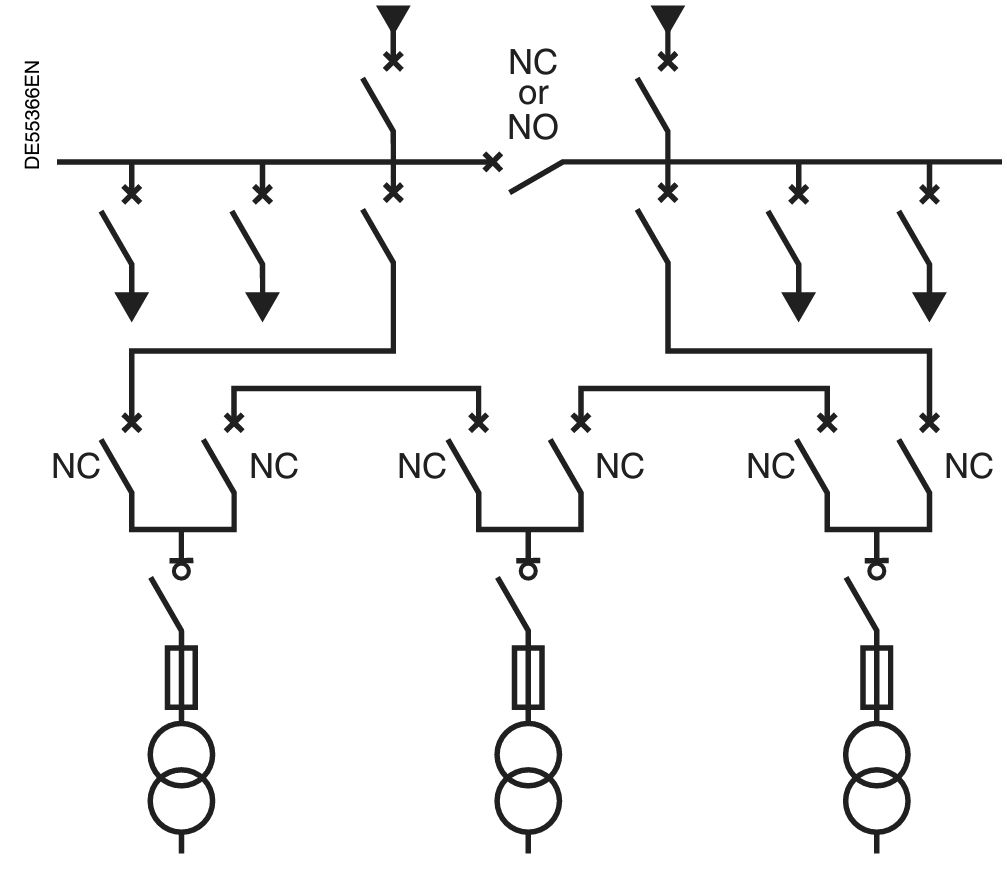

- Open Loop: Open loop configuration is very suitable for large power system operation with load concentration in different zones of a site. Open loop configuration is also flexible for major future expansion. This configuration requires automatic control function for good operation and manuver to keep the load in supply. one of its drawback is During a fault, a segment of the system might be isolated since there is no path available for supply. To tackle this issue, the next configuraton is addresed which is close loop configuration.

- Close Loop: this arguably the most expansive configuration of power system. besides this configuration requires more component, it also requires more complex protection. but it offers very high continuity without the need of automatic control functions since there is always a path for supply to reasch the load.

- Hello world!Welcome to WordPress. This is your first post. Edit or…

- Here Are Several Things to Do Before Energizing A SwitchgearYou might be familiar with the term “commissioning” especially if…

- Auxilliary Power Systemsan auxilliary power system is designed to supply and distribute…

- Power System Architecture. Which one is the Most Suitable for Your System?In planning an electrical system, one of the most important…

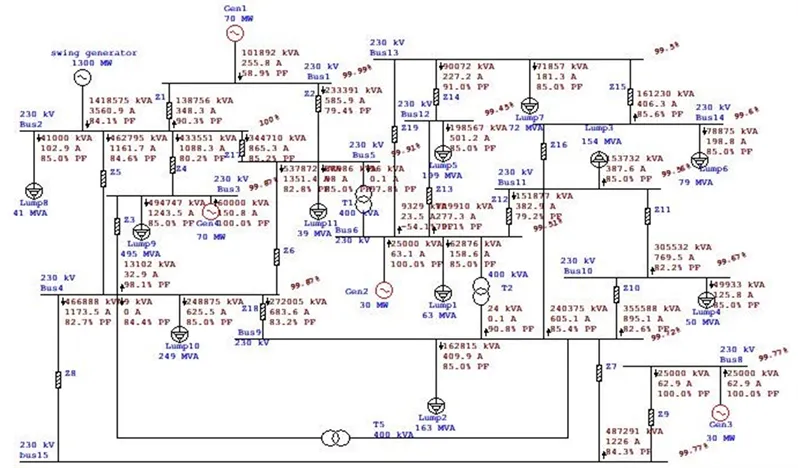

- What is Load Flow Analysis? Why is it necessery to do Load Flow Study?What is Load Flow Analysis Load Flow analysis is a…